SPEED HOSPITAL, anti Covid-19 intensive care unit

The modules for Intensive Care Unit or Vaccine Centre can be transformed into an operating block, diagnostic centre, hybrid rooms, dialysis centre, outpatient clinic, day surgery, labor-delivery block and more, according to the needs where the vaccine centre has been installed or in other new sites where it can be moved, through assembly and rearrangement.

With Speed Hospital, the hospital environments are not the ones that must adapt to the container, but it’s the modular container system that allows to set up free and well-distributed spaces, which can also be easily rearranged over time for different functions; this allows to have quick solutions today, which can be reused for different needs tomorrow, as well as being disassembled and reassembled in different sites.

A fundamental investment for the present, but which can be easily converted and reused in the future, with countless and easy transformations.

By assembling different Speed Hospital modules, a complete hospital can be created in a very short time, to be installed in areas uncovered by health services, or to replace an existing hospital to be restored.

The buyer must provide the necessary flat area with a suitable surface to accommodate the number of modules required, as well as prepare the supply and drainage networks for the Speed Hospital connection. This can be connected to the pathways of an existing hospital, with suitable connecting tunnels, or it can be mounted on its own and powered directly. The system can be equipped with special technical modules to contain power cabins, power centres, UPS, generator sets, osmotic water stations, deposits or compressors for medical gases and anything else necessary for the operation of the hospital. Speed Hospital represents a multipurpose investment, which optimizes the resources dedicated to its purchase, respecting the environment and using emission-free, recyclable materials, in compliance with all the requirements related to GPP. The structural and finishing features guarantee seismic safety, acoustic and thermohygrometric comfort.

Strenghts of Intensive Care Unit

SPEED HOSPITAL, anti Covid-19 intensive care unit

Speed Hospital is therefore designed to create intensive care units or emergency vaccine centres, autonomous or connected to existing hospitals, in order to help communities dealing with the pandemic, saving and protecting people.

The containerized Speed Hospital Intensive Care Unit has been designed to ensure the highest possible yield while maintaining the highest quality and safety standards.

The containerized Speed Hospital Intensive Care Unit can be positioned in any flat place ensuring maximum flexibility of use.

It can be positioned near hospitals (car parks or other areas) while maintaining access for the thousands of people daily involved outside the already congested hospital wards. If there is no suitable area near the hospitals or if the passage of thousands of people can be considered dangerous because of the possible congestion of car parks or access roads, you can place the Intensive Care Unit in any flat area (large antistage car parks, fairs, etc. …).

Prepared with an additional technical container containing electrical panels, air conditioning units, etc., the containerized Intensive Care Unit can be connected to the water, sewage and electrical networks already present on site or in case of absence the necessary additional equipment can be provided to make the structure totally independent.

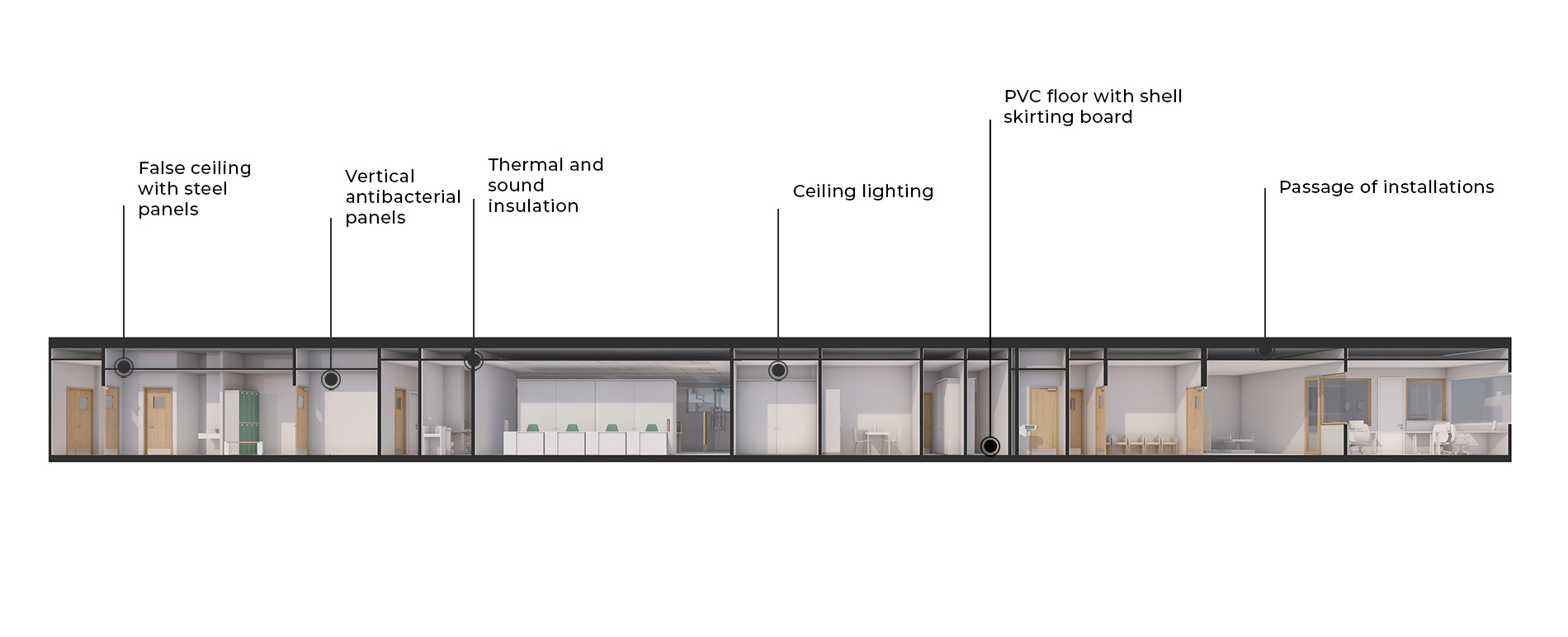

The finishing elements inside the Intensive Care Unit such as false ceilings, partitions, doors, floors, medical and non-medical furnishings, are made with the highest quality standards, perfectly washable, sanitizable and with a 10-year product guarantee.

Temporal advantages

SPEED HOSPITAL, anti Covid-19 intensive care unit

the production and preparation time of the SPEED HOSPITAL intensive care unit is expected to be 90 days from the order and approval of the executive drawnings.

the pre-assembly, that is carried out inside our warehouses, guarantees the transportation of the containers to the site planned for construction, then they are positioned, registered, fixed and connected in a very short period of time (5-8 days).

it’s the most innovative and fastest design solution currently on the market.

the SPEED HOSPITAL mobile solution allows to create a turnkey structure, fully functional and with the highest quality standards in 120 days from the customer’s order.

Pre-assembly in the workshop

SPEED HOSPITAL, anti Covid-19 intensive care unit

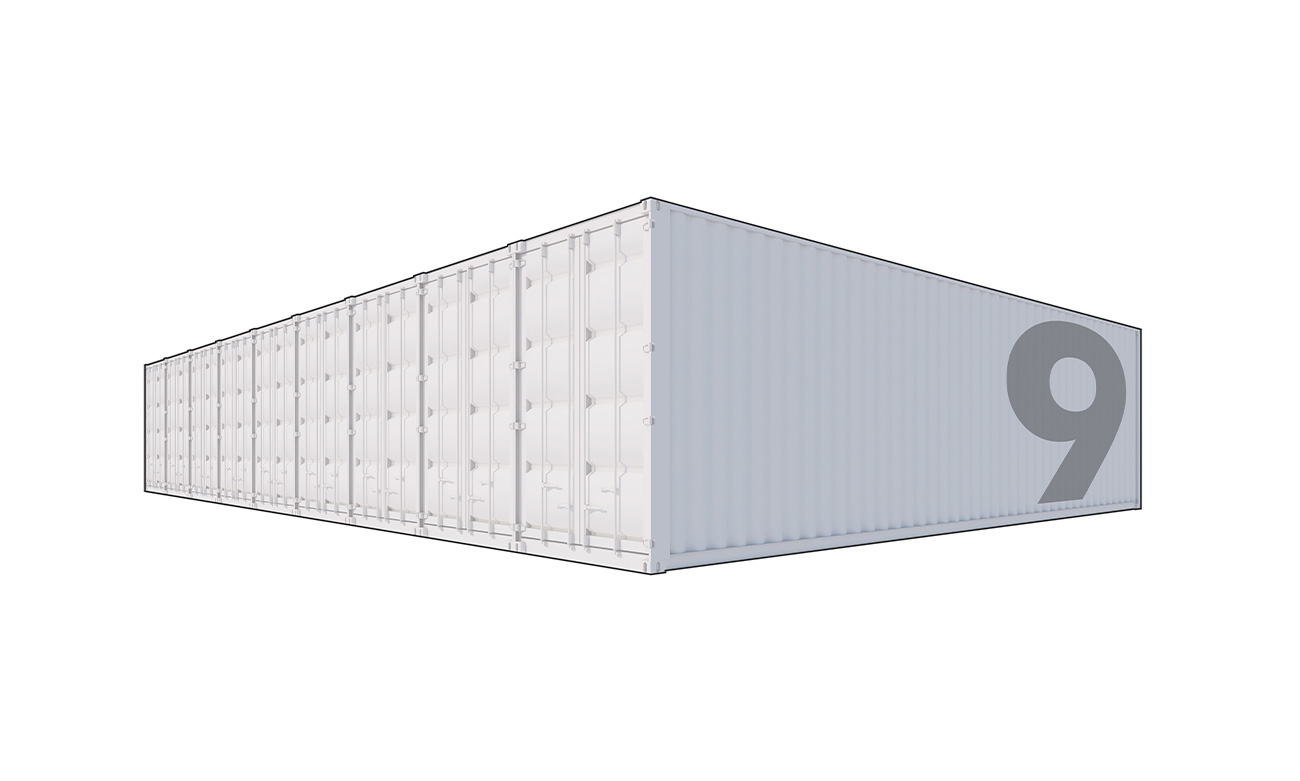

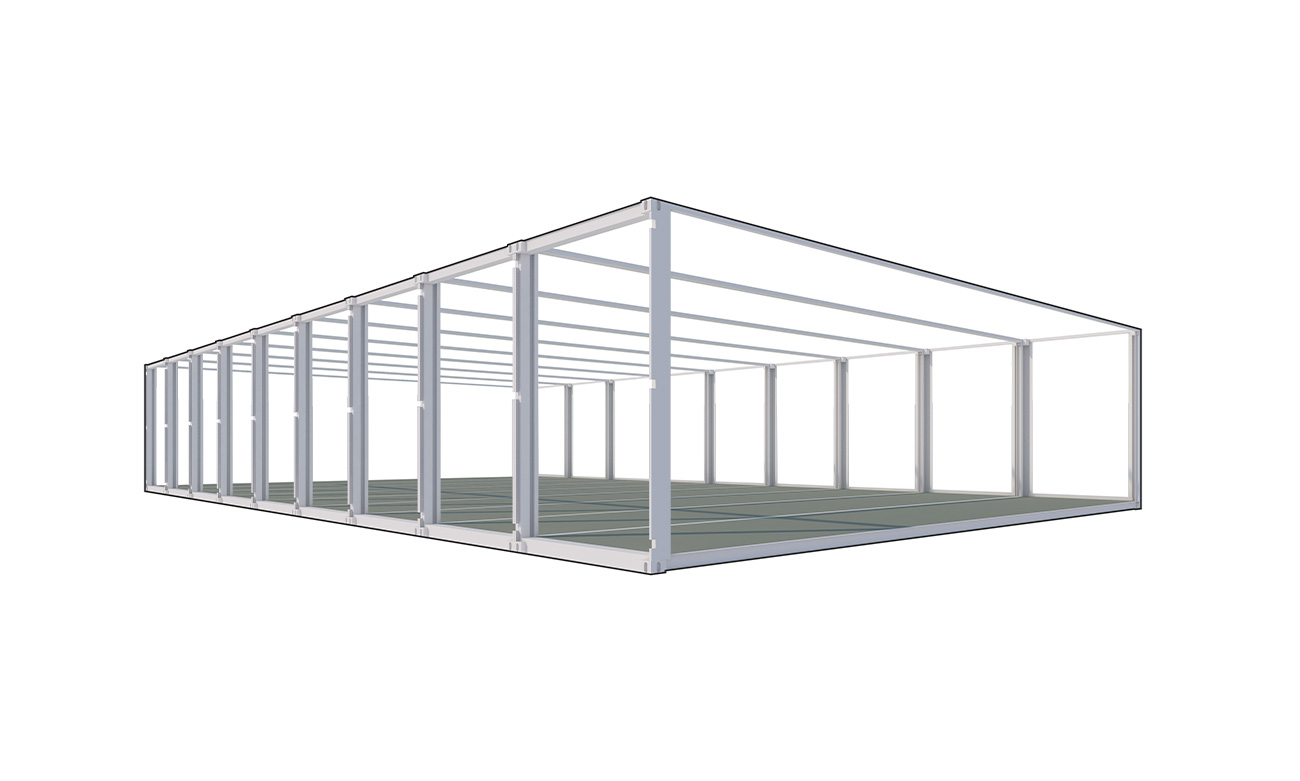

For a module type of Speed Hospital, starting from nine 40-foot containers, h. 3.80 m (Figure 1), the supporting structure of the modular system is assembled in the workshop (Figure 2).

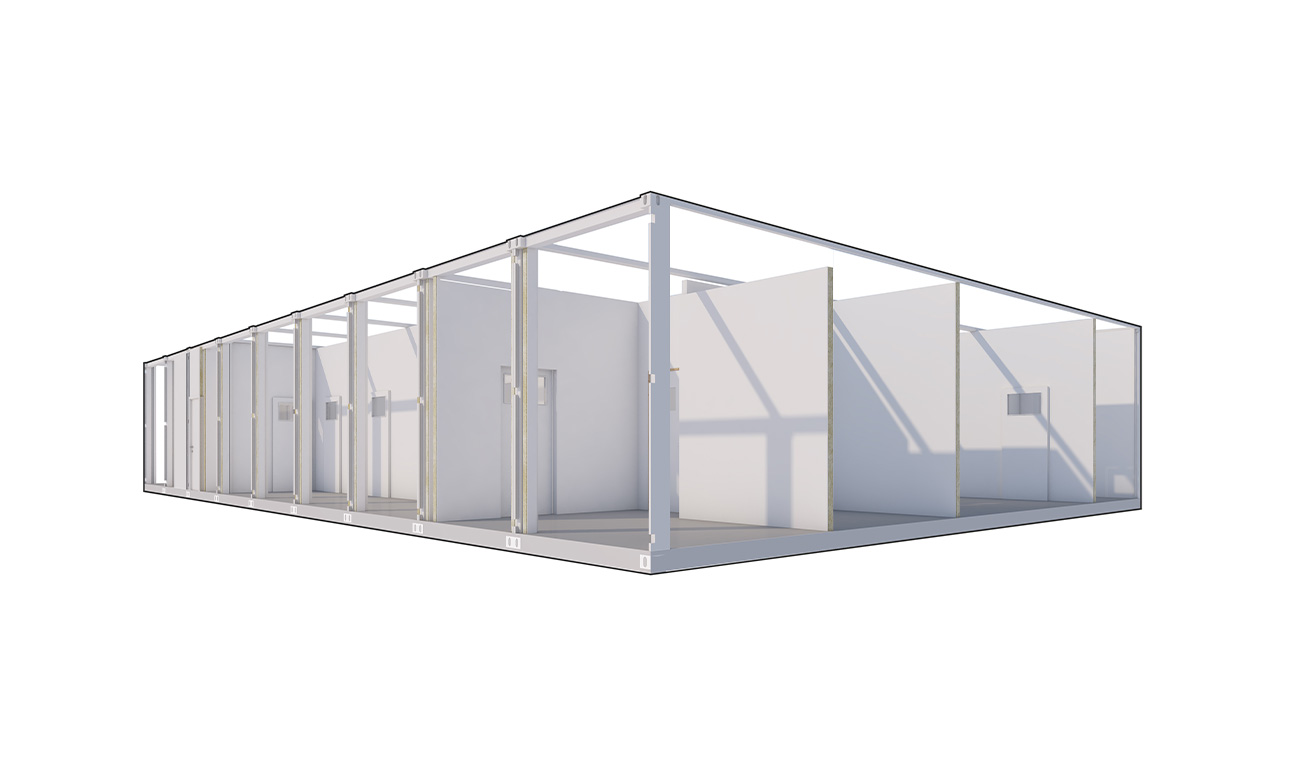

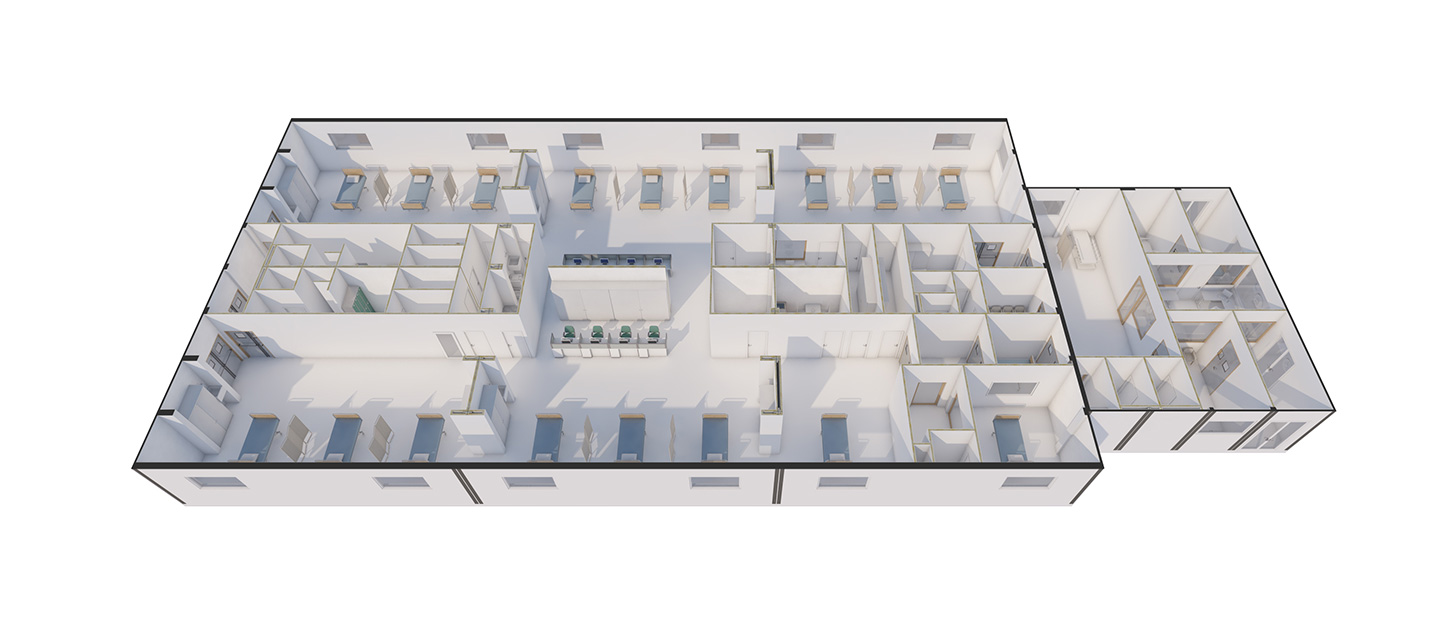

This space is set up through the internal partitions, also prefabricated (Figures 3 – 4), to which floors and false ceilings are added (Figure 5).

The premises are then completed with the construction of the systems, the assembly of fixed technologies and the preparation of integrated furnishings. The testing checks will allow the issuance of the required safety or quality certifications, already carried out in the factory. Space conception, joint construction and network sectioning are designed to allow the disassembly of the pre-assembled and verified system so that it can simply be reassembled on site, with quick couplings and without any work to be performed on site, except for the connections and the drain fittings.

The system therefore ensures maximum safety and speed of commissioning anywhere.

(figure 1)

(figure 2)

(figure 3)

(figure 4)

(figure 5)

(figure 6)

Flows and innovative pathways

SPEED HOSPITAL, anti Covid-19 intensive care unit

A modular system that creates quality spaces for patients and staff, with wide lights and well-organized distributions, far from temporary solutions made up to now with traditional containers. Inside, pre-assembled mobile walls create the partitions and support technologies, all already assembled and tested in the workshop.

Standardized elements can be envisaged for typical staff support services, unidirectional flow changing rooms for progressive ascepsis, work rooms and patient control spaces, around which variable spaces can be rearranged for most diverse functions.

The organization of pathways, the control of access and waitings with appropriate distances, always with a one-way flow from entrance to exit, allows to safely perform the services for both users and staff.

Binini Partners’ Plus Projects

SPEED HOSPITAL, anti Covid-19 intensive care unit

The design solution, developed by the architecture and engineering firm Binini Partners, a leader in the healthcare field, has implemented all the specific needs that this large-scale activity will require, optimizing spaces and pathways with the aim of obtaining the maximum possible number of beds for intensive care unit, while ensuring the protection of patients, the safety of non-immunized staff and, last but not least, the correct storage and management of vaccines.

- Modularity. The distributional and functional project is conceived on the basis of a transportable structural module

- Flexibility. The pre-assembled modules (complete with plant distributions) and aggregations can adapt to multiple functional and health needs.

- Reliability. An industrialized prefabrication process that guarantess high quality, durability and efficiency thanks to the materials used.

- Installation. The unit is complete in all its components.

- Accreditation. The functional unit’s aim is to comply with national standards and guidelines for health accreditation.

- Well-defined and separeted pathways for clean and dirty materials.

A ward with a large open space room that accomodates 16 beds, flanked by an isolated patient area, equipped with a filter at the entrance, placed close to the entrance to the ward in order to avoid long journeys. The isolated station is visible from the corridor through a large window. - The observation and monitoring areas are placed in front of beds and consist of large counters.

- Diversified entrances for staff and patients.

- Integrated medical-nursing assistance.

- Layout capable of combining safety for patients and healthcare workers with the functionality of spaces.

- Basic module able to adapt quickly to differtent functional and health needs.

- Costumized operating unit configurations based on specific custumer requests: intensive care, operating blocks, polyclinic areas, diagnostic areas, obstetrics department, etc.

- Possibility of reconversion at a later time based on new contingencies.

- Autonomous, modular and sustainable ward, where architecture, medicine and engineering find a point of contact and strenght. Built around the patient.

- Well-organized daily workflow, in terms of structure and productivity.

- In order to design an advanced ICU, the human element was taken into account, balancing the functionality of medical equipment with a design composed of glass, natural light ( visual openings to the outside and the sorrounding landscapes) and soothing colours.

Binini Partners’ Architecture

SPEED HOSPITAL, anti Covid-19 intensive care unit

The conceived design is rigorous and essential, lending itself to the most different external cladding solutions, materials and finishes, also functional for the flexible aggregation of several basic modules, to obtain the required surfaces. Image, colours and architectural coatings are completely customizable depending on the brand and the world to which it refers.

The available range can go from the painted basic module to the most iconic coating solutions, always respecting cost-protection and the correct use of resources in the interest of patients.

The Intensive Care Unit after Covid-19

SPEED HOSPITAL, anti Covid-19 intensive care unit

With the clear intention to transform a necessary expenditure (such as the conversion of a hospital ward for the Covid-19 vaccine centre) into an investment for the future, we have developed a series of solutions that can convert, through minimal interventions , the Intensive Care Unit into hybrid rooms, dyliasis centres, polyclinics, day surgery labor-delivery blocks or other possible solutions useful to the health system in the future. When the Intensive Care Unit will not be necessary anymore and if there is not immediate need for conversion to other environments, the diassembly of the structure and the sealing of the individual containers can be carried out (5-8 days) and then relocated to another place with the same need or by placing the containers in storage waiting for future use.

How to reuse the Intensive Care Unit

SPEED HOSPITAL, anti Covid-19 intensive care unit

How to reuse the containerized Intensive Care Unit after the pandemic

Disassembly and storage for future needs

Disassembly and storage for future needs

Disassembly and relocation to another place for the same need

Disassembly and relocation to another place for the same need

Reorganization of spaces for new needs

Reorganization of spaces for new needs

Legenda dei percorsi

Simbolo |

Descrizione |

|---|---|

Pazienti

|

|

PERSONALE

|

|

PUBBLICO

|

|

MATERIALI E SERVIZI

|

|

MATERIALI E SERVIZI

|

|

USCITE DI SICUREZZA |